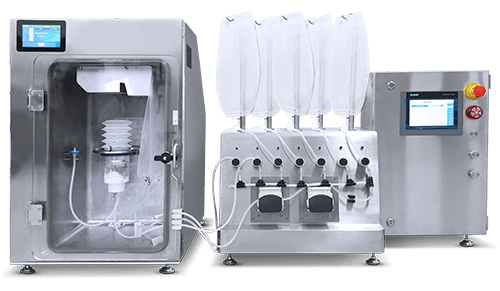

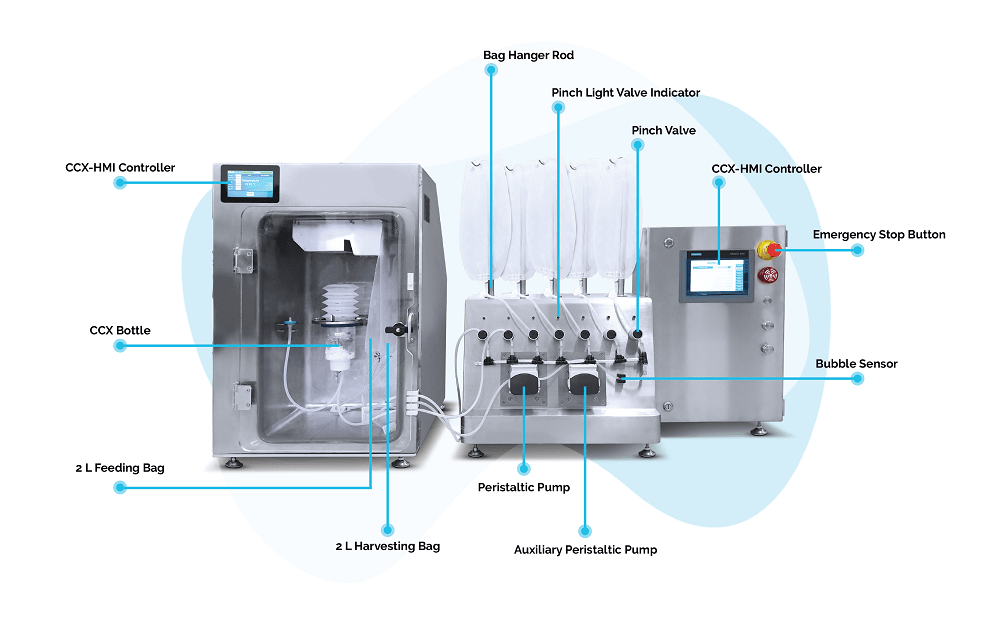

CelCradle X® Semi-Automated Harvester

The Cradle's Harvester Partner

The CelCradle X Semi-Automated Harvesting System (CCX-SAH) is used to harvest whole cells from the CelCradle and CelCradle X® bottles through automation by setting up various parameters.

The semi automatic cell harvesting is achieved through the mounted peristaltic pumps that allow liquid addition/removal and whole cell harvest during the harvesting process.

This semi-automated cell harvesting of adherent CelCradle cultures includes but not limited to: Insect Cell, Mammalian Cell, Stem Cells. Aside from semi-automatic cell harvesting of adherent cells, obtaining intracellular viruses is also possible with CCX-SAH.