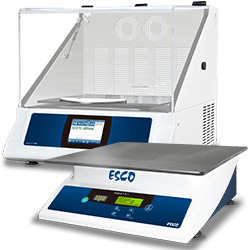

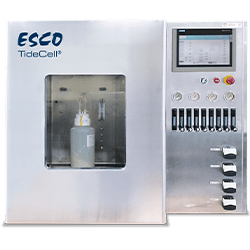

Esco Bioprocessing Products

Esco leverages its expertise in life science manufacturing to provide end-to-end solutions for bioprocessing equipment and tools ranging from upstream to downstream applications.

We cater bioprocessing products intended for different stages of the bioprocessing workflow as follows:

Upstream bioprocessing

- Material and Reagent Preparation

- Manipulation

- Cultivation

Downstream bioprocessing

- Isolation

- Purification

- Concentration

Formulation and Filling

- Formulation into final vessel