TideXcell® Harvesting System

The Gentle Giant's Harvester Partner

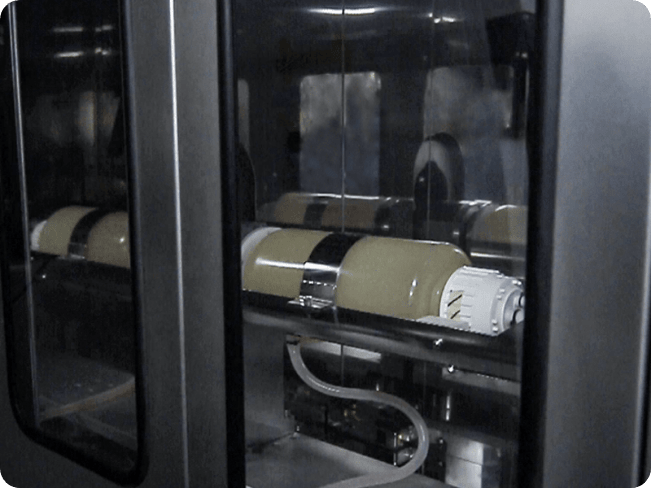

Disconnect the TideXcell® matrix vessel with the mixer. Mount and fix the TideXcell® matrix vessel in the THS and connect the vessel with tubing manifolds that provide the sources. The six sources connect with the matrix vessel through 6 peristaltic pumps.

Note: Connection of tubings should be done inside a biological safety cabinetPump in and out chosen dissociation enzyme or equivalent solution to digest cells from the matrix. Incubate matrix vessel after pumping of enzyme.

*Incubation time might be longer or shorter depends on the condition and needs to be determined beforehand

Note: Incubation time might be longer or shorter depending on the cell culture requirements. This needs to be determined beforehand prior to running the cell culture harvester.| Infrastructure | Exterior dimesion (WxDxH) |

Controller unit: 80cm x 91cm x 181.2cm Main chamber: 110cm x 110cm x 188.7cm |

| Weight | 1,330 kg not including 2/20L adaptor (18kg) | |

| Power | Single phase, AC, 220 V, 50/50 Hz | |

| Gas Input | At least 0.5 MPa from the air source | |

| Other | RS485 communication port | |

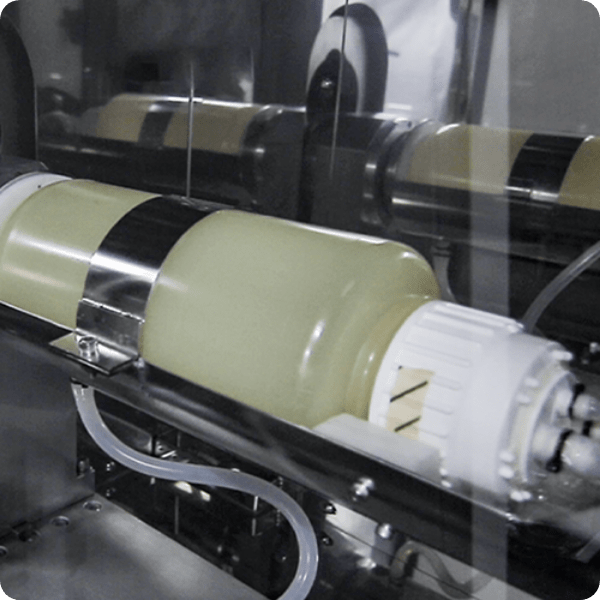

| Function: Rotation | Functional unit | Rotary motor |

| Work | 750 W | |

| Range | 0°~180° (back and forth) | |

| Rate | 0~10 rpm ± 2 rpm | |

| Period | 0~999 sec ± 5 sec | |

| Function: Shake | Functional unit | Shake motor |

| Work | 3.5 kW at 300 rpm | |

| Range | 13cmmax | |

| Rate | 50~300 rpm ± 10 rpm | |

| Period | 0~999 sec ± 5 sec(16.6 mins) | |

| Function: Break | Functional unit | Damper |

| Function: Feed and Harvest | Functional unit | 6 Peristaltic pumps (Harvest Out, Buffer Saline In, Enzyme In, Inhibition In, Culture Medium In, Waste Recovery) |

| Rate | 20 - 250 rpm ± 5 rpm | |

| Period | 0~999 sec ± 5 sec | |

| Tubing | ID 9.6 mm(3/8")*WT 32 mm(1/8") | |

| Consumable: Matrix vessel | Volume | 2 L and 20 L |

| Material | PP | |

| Consumable: Tubing set | Type | ID:3/8", OD:5/8" |

| Tool: Torque wrench | Range | 10~45 N•m |

| Control: Touch panel | Size | 10.4" color |

| Modes | Automated and manual | |

| Efficiency | Cell recovery rate |

2L Vessel: >90% recovery rate 20L Vessel: 70%~90% recovery rate |

Sign up to our newsletter and receive the latest news and updates about our products!