VXL™Hybrid Bioreactor

Your 4-in-1 Bioreactor

| Control Unit Weight | |

| Single | 80 kg (177lbs) |

| Control Unit Dimensions | |

| Single | W460x D 637 x H 903 mm |

| Utility Connections | |

| Power Supply | 220 volts, max power consumption 5A |

| Gases |

4x6mm external tubing diameter Gas supply pressure, 10psi oil & moisture-free |

| Water |

Water supply pressure- 1.5 M Flow rate up to 10-12 lpm Minimum temperature 13-14°C L/S 35 Silicone for tubing |

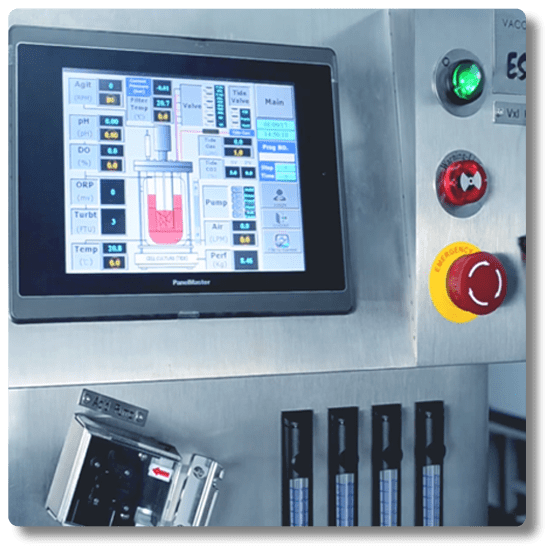

| Control Unit | |

| Housing | Stainless Steel, AISI 304 |

| Display | HMI |

| Resolution | 800x600 |

| SCADA Communication | Ethernet |

| Safety valve gas pressure | 10 psi for Matrix Reactor Vessel and Suspension Vessel |

| Water inlet pressure reduction | 0.15bar, integrated pressure control |

| Motor Drive | |

| Direct Drive | Power: 400W |

| Reactor Vessel Material | |

|

1 Liter and 7 Liter vessel Total Volume: 1.5L and 8.2L |

Borosilicate glass |

| 14 Liter vessel | Borosilicate glass/Stainless Steel |

| 25 Liter vessel | Stainless Steel |

| 50 Liter vessel | Stainless Steel |

| Vessel Dimensions | |

| 1 Liter | D 116 x H 148 mm |

| 7 Liter | D 190 x H 320 mm |

| 14 Liter | D 240 x H 450mm |

|

Sensor | Measurement Range | Display Accuracy |

Description | |

|---|---|---|

| Temperature | PT-100 class A ; Deviation: ±(0.15+0.00 |t| ); 0°C-100°C | |

| Dissolved oxygen | Measurement Principle | Amperometric/ Polarographic |

| Working Conditions | ||

| Pressure resistance measurement | 0.2-6 bar absolute | |

| (2.9-87.0 psi absolute) | ||

| Mechanical resistance measurement | max. 12 bar absolute | |

| (174.0 psi absolute) | ||

| Measuring temperature range | 0...80°C (32…176 °F) | |

| Temperature range |

-5…140°C (23…284°F) (autoclavable) |

|

| Construction | ||

| Temperature compensation | Automatic with built-in RTD | |

| Cable connection |

VarioPin (IP 68) straight or angled K8S straight (digital ISM sensors) |

|

| O-ring materia | Silicone FDA and USPP VI approved | |

| Membrane material |

PTFE/Silicone/PTFE (reinforced with steel mesh) |

|

| Wetted metal parts |

Stainless steel Special material on request |

|

| Surface roughness of wetted metal parts (ISO 1320:1992) | N5 (< 0.4m [16in]) | |

| Quick disconnect interior body | Standard | |

| Cathode | Pt | |

| Anode | Ag | |

| Guard ring | No | |

| Dimensions | ||

| Sensor diameter | 12 or 25 mm (0.47” or 0.96”) | |

| Immersion length (a) for 12 mm sensor |

70, 120, 220, 320, 420 mm. (2.8, 4.7, 8.66, 12.6, 16.54”) |

|

| Immersion length (a) for 25 mm sensor |

80, 160, 260, 360 mm (3.15, 6.3, 10.24, 10.17”) |

|

| Performances | ||

| Detection limit | 6ppb | |

| Accuracy |

≤ ±(1% + 6 ppb) of reading in liquids |

|

| Response time at 25°C/77°F (air – N2) | 98% of final value <90s | |

| Sensor signal in ambient air (25°C/ 77°F) | 50…110nA | |

| Residual signal in oxygen-free medium | <0.1% of the signal in ambient air | |

| Maximum flow error | ≤ 5% | |

| Certification | ||

| EHEDG, 3A | Yes | |

| 3.1B (EN 10204.3/1.b) | Yes | |

| ATEX certificate | Yes | |

| FM Approval | Yes | |

| FDA/USP VI | Yes | |

| Quality control | Yes | |

| pH | Measuring range | pH 0…14 |

| Temperature |

0…80°C for operation 0…140°C for sterilization |

|

| Pressure resistance | Up to overpressure of max. 6 bar (87psi) | |

| Reference system | Argenthal (Ag/AgCl) | |

| Reference electrolyte | Gel electrolyte | |

| Diaphragm | 1 ceramic diaphragm | |

| Glass membrane | HA, high alkali glass quality | |

| Glass shaft | Ø12 mm | |

| Plug head | K8S, Pg 13.5 thread | |

| Foam Control | Teflon insulated stainless steel | |

| Level | Teflon insulated stainless steel | |

| Turbidity | Dimension | W 270 x D 200 x H 300 mm |

| Measuring principle | Backscatter, 1-fiber | |

| Sensor material | DIN 1.4435 (316L) | |

| Sensor diameter | 12 mm | |

| Insertion length | 120, 205, 297, or 407 mm | |

| Process connection | Pg 13.5 | |

| Measuring range | ||

| Formazin Turbidity Units 1 | 10…40000 FTU | |

| Suspended Solids (Diatomaceous earth as reference) | 0…250 g/L | |

| Design | ||

| Cable connectors | SMA | |

| Cable lengths | 3m (10ft) optica | |

| Cable type | Duplex HCS fiber, fixed | |

| Wetted parts | ||

| Metals | DIN 1.4435 (316L) | |

| Plastic | None | |

| O-ring | Viton-FDA | |

| Sapphire spigot for fiber | None | |

| Sapphire window for fiber protection | None | |

| Working conditions: | ||

| Pressure range | 0…6 bar (0…87psi) | |

| Redox | Dimension | W 270 x D 170 x H 230 mm |

| Measuring range | pH 0…12 | |

| Temperature |

0…100°C in operation 0…130°C for sterilization |

|

| Pressure resistance |

From vacuum up to a process pressure of max 2.5 bar (36psi) |

|

| Reference system | Argenthal (Ag/AgCl) | |

| Reference electrolyte | Pressurized gel electrolyte | |

| Diaphragm | 1 ceramic diaphragm | |

| Glass shaft | Ø12 mm | |

| Plug head | K8S, Pg 13.5 thread | |

| RM load cells |

Weight:100 kg Dimensions: (in mm) 330 X 330 |

|

| Model | M-1000 | M-5000 |

|---|---|---|

| Total Volume (L) | 1.5 | 8.2 |

| Maximum Working Volume (L) for Suspension Culture | 0.6-1.1 | 4.5-7 |

| Depth (mm) | 116 | 190 |

| Height (mm) | 148 | 320 |

| Recommended BioNOC II Matrix volume [ml] | 180 | 1000 |

| Recommended amount BioNOC II Matrix in grams | 10 | 55 |

| Aspect Ratio | 1:2.5 (for suspension) 1:3 (for microbial culture) | |

| Specifications* of 4-in 1 VXL Hybrid Bioreactor | Adherent Cell Culture | Suspension Cell Culture | Fermentation | Microcarrier-Based Cell Culture | ||||

|---|---|---|---|---|---|---|---|---|

| Model | M-1000 | M-5000 | M-1000 | M-5000 | M-1000 | M-5000 | M-1000 | M-5000 |

| Vessel Material | Borosilicate Glass | |||||||

| Temperature Range | 20ºC - 70ºC Precision: 0.1 ºC | 10 ºC-70 ºC Precision: 0.1 ºC | 20 ºC-70 ºC Precision: 0.1 ºC | 10 ºC-70 ºC Precision: 0.1 ºC | 20 ºC-70 ºC Precision: 0.1 ºC | 10 ºC-70 ºC Precision: 0.1 ºC | 20 ºC-70 ºC Precision: 0.1 ºC | 10 ºC-70 ºC Precision: 0.1 ºC |

| Baffle | N/A | YES | YES | N/A | ||||

| Top Stirrer Motor | 10-1200rpm | |||||||

| Impeller speed | 25-200r pm | 50-1200 rpm | 50-1200 rpm | 25-400 rpm | ||||

| Impeller Design** | Small 6-Blade Rushton Turbine | 3-Pitched-Blade Turbine and 3-Marine-Blade Propeller | Large 6-Blade Rushton Turbine | 3-Pitched-Blade Turbine and 3-Marine-Blade Propeller | ||||

| Ventilation | Ring Sparger | Micro-Sparger | Ring Sparger | Ring Sparger | ||||

| Drive Method | Tide: KNF brushless motor with air pump, controlled by PID or constant voltage direct drive. Mixing: Top direct servo motor with PID/PWM control | Mixing: Top direct servo motor with PID/PWM control | ||||||

| Condenser | Stainless steel condenser with 0.2 um disk type or cartridge type filter | |||||||

| pH Range | pH 4-14 Precision: 0.01 | |||||||

| DO Range | 0-100 % Precision: 0.01% | |||||||

| Aeration | 10L/min Precision: 2% | |||||||

| Emerging Time | 0-100mins | N/A | ||||||

| Submerging Time | 0-100mins | N/A | ||||||

| Liquid Level Control | High Level Sensor | Electronic Scale | ||||||

| Sampling | liquid: sampling bottle; matrix: sample port | liquid: sampling bottle | ||||||

| Foaming Control | N/A | YES | YES | YES | ||||

| Control Unit | 8.4” HMI | |||||||

Sign up to our newsletter and receive the latest news and updates about our products!