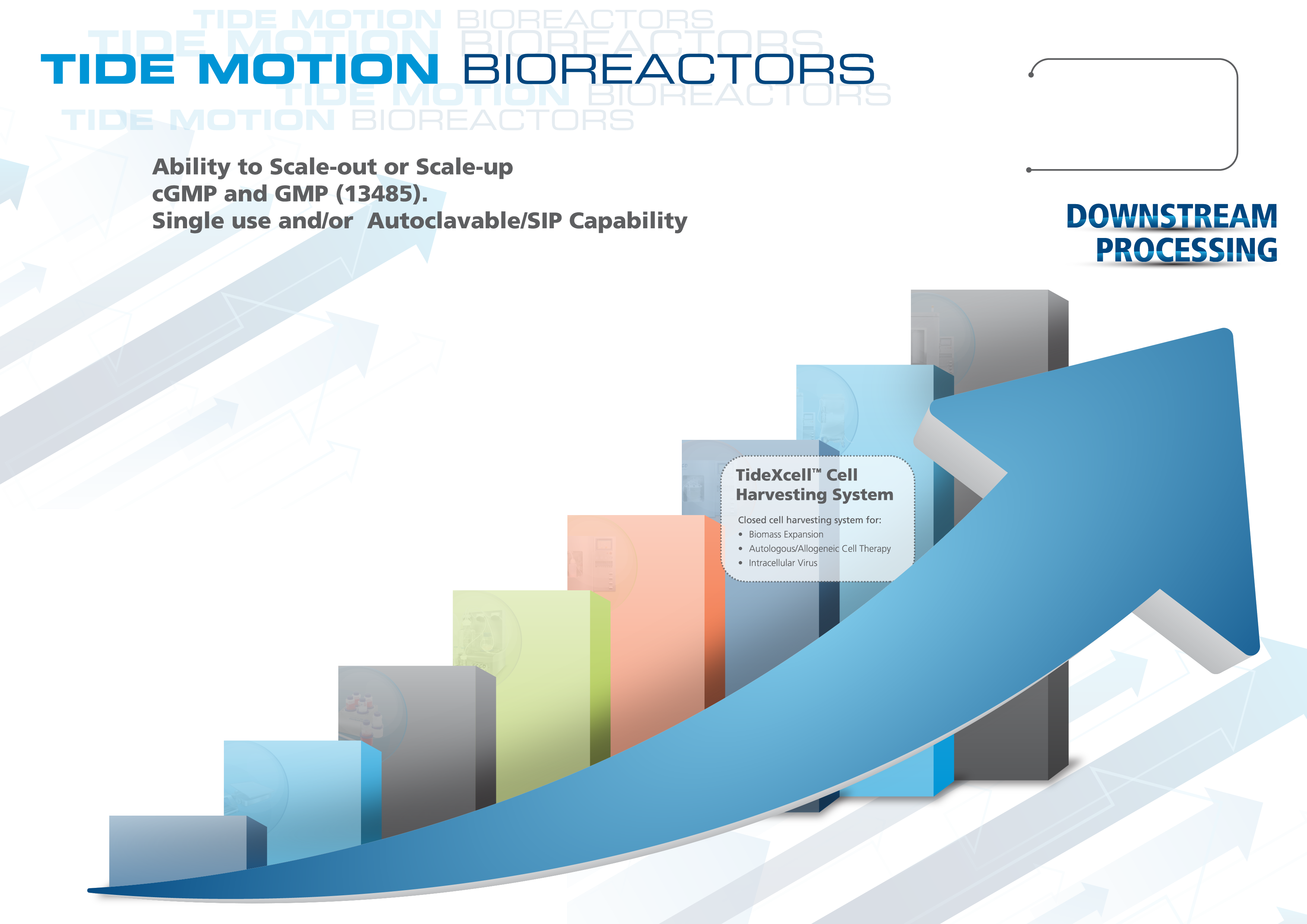

Tide Motion Bioreactors

Linearly Scalable bioreactors

TideXcell™

3,500 up to 5,000 L

Tide 2mm/s: 3,000 - 5,000 L (st. st. tanks)

Tide 6mm/s: 55,000 L

Large st. st. tank,scale for secreted virus production, viral vectors, cellular agriculture (optional edible scaffolds), or biosimilars/biobetters

TideXcell™

300 L

TideXcell™

100 L

TideXcell™

20 L

TideXcell™

2 L

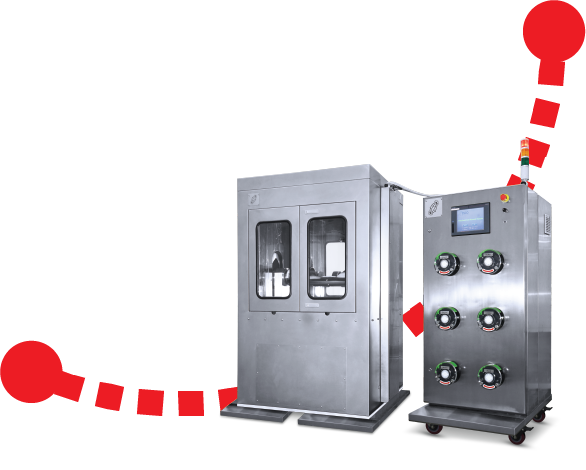

CelCradle ™

with Semi-automated Harvester Esco standalone bioreactor. Single Bottle, Optional Docking to Isolator.

CelCradle™ + CelShaker™

Early stage research and development. One stage can occupy 4 CelCradle bottles, integrated inside client's CO2 incubator. Manual control

CelXrocker™

2D Tide proof of concept (POC) quick data seed ~20,000-60,000 cells per carrier

Sign up to our newsletter and receive the latest news and updates about our products!