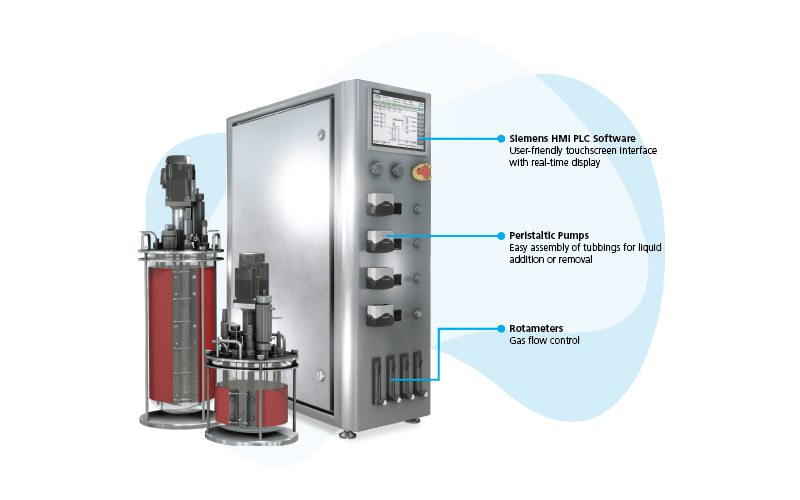

BioXcell® Small-Scale Stirred Tank Bioreactor

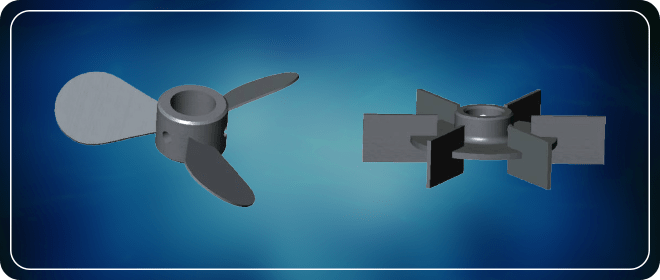

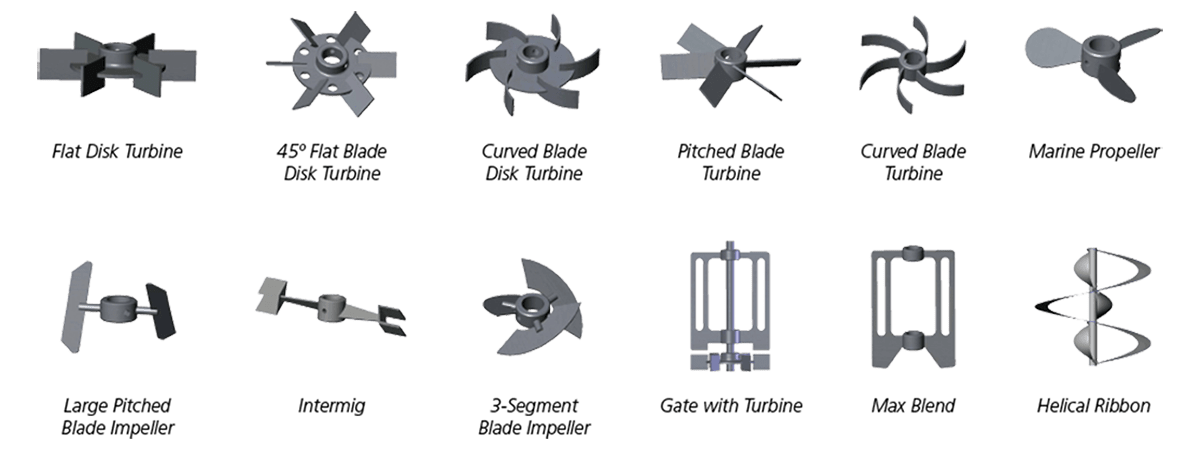

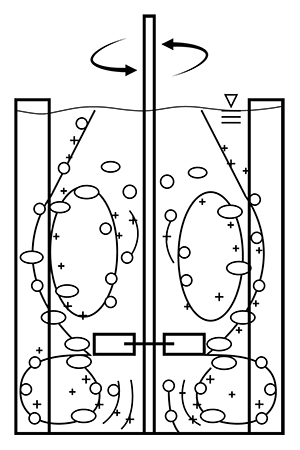

Excellent Versatility for Microbial Culture SuccessStirred tank bioreactor systems have long been around since the beginning of culturing different agents such as cells, enzymes, or antibodies. The BioXcell is a stirred tank bioreactor for small-scale research and development applications that is available in single-use or multiple-use vessels. This compact design stirred tank bioreactor entails small footprint to save space in your laboratory. Its control tower is combined with either 2 L or 10 L vessel for microbial, fermentation, and cell culture applications. Whether you are at an early stage of your research and development, this bioreactor is available in flexible configuration to suit your needs.