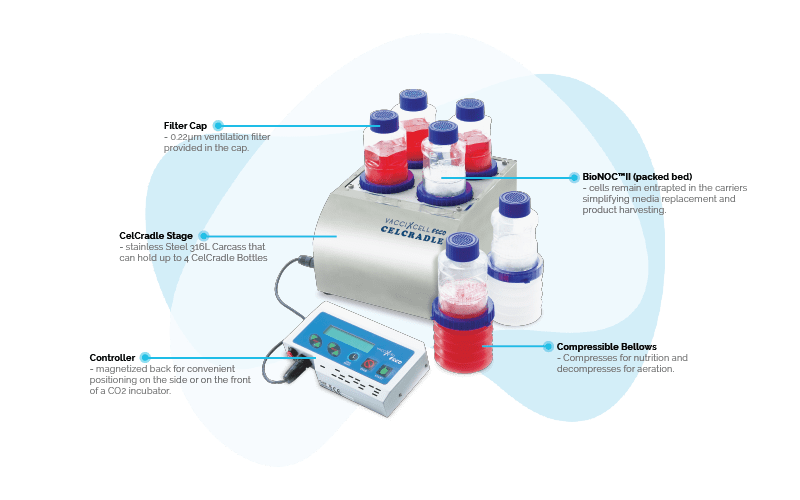

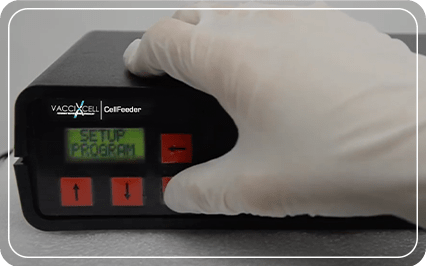

CelCradle® Benchtop bioreactor

Cradle for your Adherent Cells

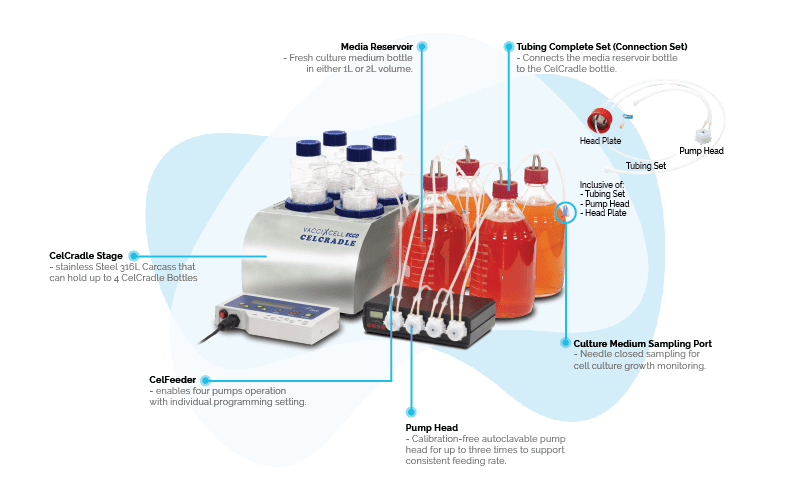

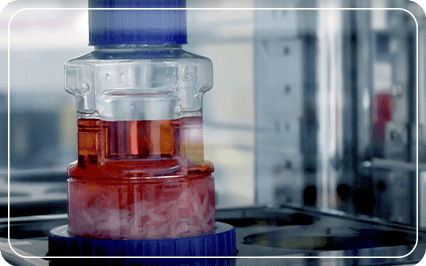

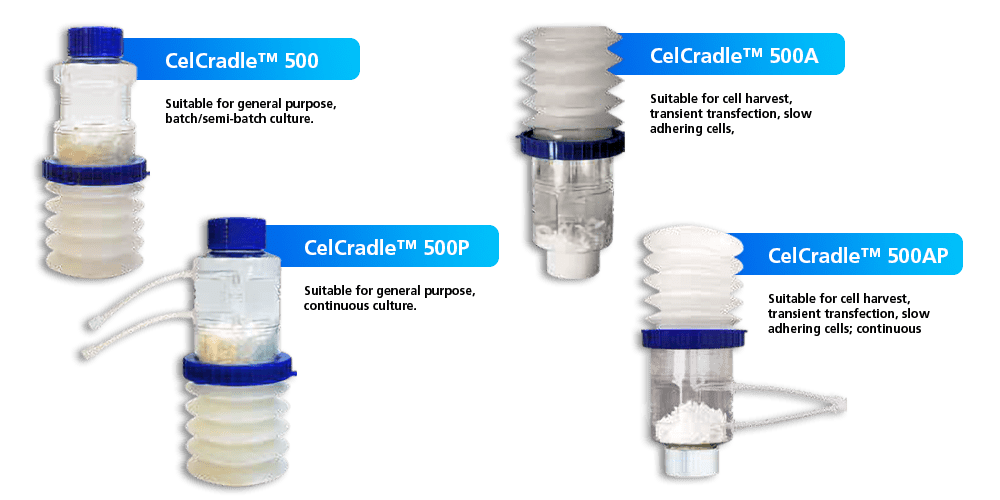

CelCradle is a bench-scale bioreactor system that can support high adherent cell density culture. It is a single-use, cost effective packed-bed bioreactor system for adherent scale-up from laboratory scale to production scale. This disposable bioreactor fits inside a 6ft3 CO2 incubator (for batch culture) or 8.5ft3 CO2 incubator (for perfusion culture).

The ready-to-use bottles, as part of single-use manufacturing, helps eliminate validation costs as compared to multiple-use system when starting on your next cell culture run. The system components come pre-sterilized, pre-packed that speed up your research whether for vaccine, stem cell, or viral production applications.