Applications

Roller Bottle System

Roller bottles are disposable, cylindrical bottles that are placed inside an incubators and rotated typically between 5 and 240 rph. The surface area of the bottles are around 500-1700cm2 which makes them suitable for culture volumes of 0.1-0.3 L.

Anchorage-dependent cells will attach to the surface of the bottle and through rotating motion, the cells will be alternately exposed to gases in the bottle headspace and nutrition from culture medium. As this system is manually controlled, monitoring culture parameters like pH, DO, and nutrient amount is difficult. Scaling cannot also be done through increasing the bottle size. Instead, scaling out the system, increasing the number of bottles. This process will be difficult especially when under manufacturing applications.

CelCradle™ Equivalence

Esco VacciXcell’s tide motion bioreactor system is similar to the principle of roller bottle system, as it also alternately exposes the cells to aeration and nutrition. However, the tide motion system overcomes most of the disadvantages associated with the roller bottle system as well as other static cell culture system including space requirement, amount of labor, contamination risk and most importantly production capacity.

It is designed based on the concept of bellow-induced intermittent flow of media and air through porous matrices, where cells reside. Celcradle™ provides a low shear, high aeration, and foam-free culture environment which results to high density cell culture with high quality product yield, minimal downstream processing cost, minimal labor and space requirement and most importantly highly reproducible and linearly scalable results.

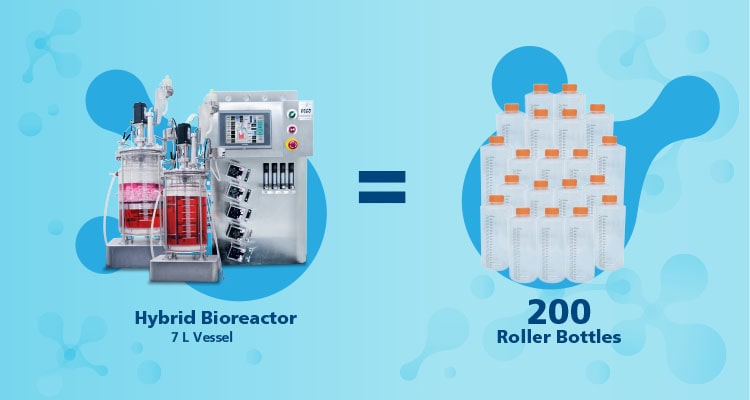

VXL™ Hybrid Equivalence

Esco VacciXcell ™ Hybrid Bioreactor offers best transferring processes and analytical methods from research and development sites to commercial manufacturing sites. In a start-up or R&D environment, determining which type of culture would yield the desired product the most is essential.

The Esco VacciXcell ™ hybrid bioreactor gives its users exactly that option by being able to try out four (4) different types of culture namely: adherent culture using macrocarrier, adherent culture using microcarrier in a stirred tank environment, suspension culture and fermentation. By being able to do the design of experiment (DOE) using these four types of culture in one system, data gathering and analysis would be easier and more efficient, resulting in lower total cost and shorter process development period.

TideXcell™ Equivalence

As costs of production become more and more expensive, existing facilities that employ the roller bottle system can thereby benefit from switching to TideXcell™ System for several reasons.

The TideXcell™ System is Esco VacciXcell’s tide motion bioreactor which is linearly scalable from laboratory to production scale with significant reduction of bioprocessing time and costs. The system can replace thousands of 850cm2 roller bottles for up to 20,000 pieces with small footprint. The TideXcell™ System is fully enclosed and automated which reduces the risk of contamination and increases the control of the production. The tide motion principle employed in the TideXcell™ system allows simple medium exchange and better medium consumption efficiency, which is a large cost in cell culture systems.