Applications

Microcarriers to Closed System

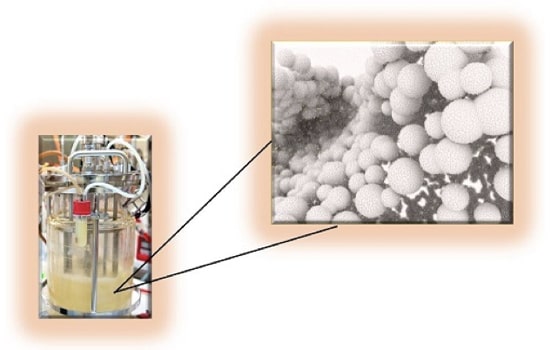

Microcarriers are microbeads, to which cells attach and grow on the surfaces. They are then suspended in culture medium in a stirred tank bioreactor, where the medium is continuously agitated for nutrient and oxygen transfer. However, several factors like fluid-induced shear stress, collisions, and mechanical stirring can damage cells causing apoptosis or cell death. Cell death causes two main difficulties in bioreactor systems: first, it decreases product yield and second, it adds more downstream processing steps and thus, higher cost due to increased cell debris in the harvested medium.

Limitations of Microcarriers in High Density Cell Culture

Microcarriers have been widely used for high density cell culture. These microcarriers are added into stirred tank bioreactors to which the adherent cells bind to grow and proliferate. While microcarriers can be a vital part in high density cell culture, it also poses significant limitations which makes the process of cell culture very laborious and expensive.

Some limitations include:

- A stirred tank reactor utilizes agititation in order to make a homogenous cell culture system. However, agitation leads to the generation of turbulence thus exposing the microcarrier-bound-cells to be subjected to mechanical shear stress which causes apoptosis or cell death.

- Eddy, which is generated from fluid turbulence, also directly interacts with the adherent cells which significantly damages the cells and results to greater number of cell debris and thus low cell yield and added downstream processing costs.

- Increasing the number of microcarriers used will lead to higher density cell culture however this leads to higher degree of collisions (i.e. bead-to-bead or microcarrier-bound-cells to mechanical impeller). When cells collide with each other it incurs great damage in them and results to cell death and decreased cell yield.

- Scale-up is a very critical issue in microcarrier based cell culture. Higher energy dissipation causes the cells to experience stress which in turn leads to cell death.

- Spargers, which produces bubbles, are used to induce oxygen in the system. However, the bubbles formed by the sparger can entrap the microcarriers with cells bound into them. This phenomenon leads to great decrease of cell yield due to cell death.

- Foaming and bubbling can be reduced by adding anti-foaming agents in the system but these chemicals can also be damaging to the cells and cause cell death..

Tide Motion System

Esco VacciXcell’s Tide Motion Bioreactors eliminates all these limitations by utilizing tide motion principle which is the gentle vertical oscilation of culture medium into and out of the matrix vessel which intermittently exposes the cells to aeration and nutrition. Integration of tide motion principle makes our bioreactors produce high quality and great quantity of cells due to extremely low shear stress, equal nutrition distribution and no oxygen limitation which leads to minimal downstream processing and reduced production cost. Our bioreactors can also be integrated to an isolator which totally eliminates the possibility of contamination. Lastly, Esco VacciXcell offers true linear scalability platform where scaling up is as easy as adding equipment with higher volume capacity but the bioprocessing principle is the same.