StirCradle™-Pro Large Scale Stirred Tank Bioreactor

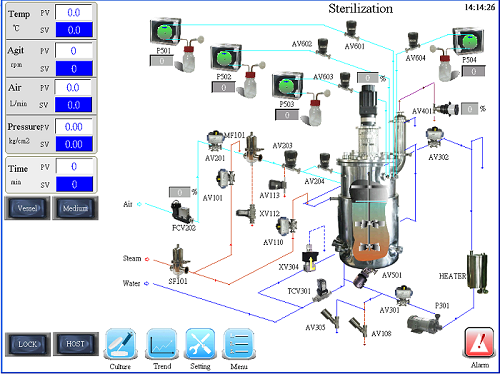

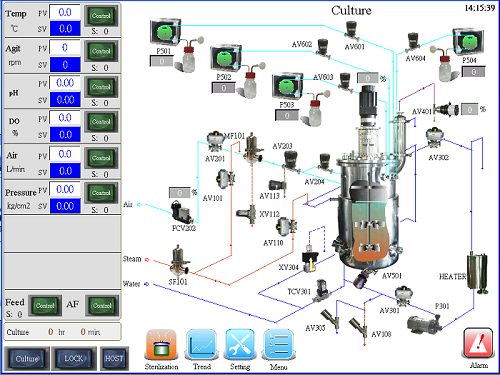

Stirred Tank Bioreactor PartnerThe StirCradle-Pro is a fully stainless steel fermenter/bioreactor system designed with an automated 5-step cycle SIP system for both culture medium and reactor vessel. Esco VacciXcell offers a wide range of large scale bioreactors capacities from 20L up to 1000L. However, customized reactor sizes are available should the users require a customized bioreactor for large scale culture of cells.

StirCradle-Pro features various advanced design and assembly to facilitate the fermentation/culture process including reactor design that eliminates blind spots and increases oxygen retention rate, lifting system for easy cleaning of reactor vessel, and LED light for easy viewing within the culture tank.

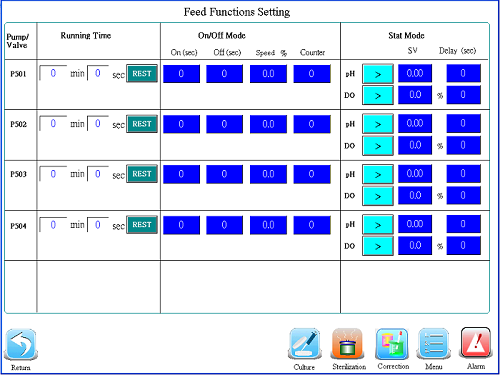

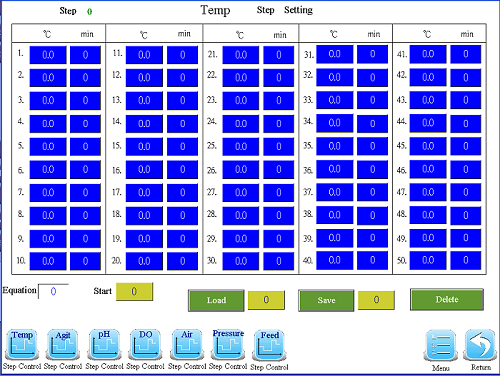

Esco VacciXcell simplifies scale up from the laboratory to pilot and production scale by providing analysis data as reference for scale-up conditions. Apart from customized sizes, Esco VacciXcell also offers parametric programming and special vessel development to help speed up the experiment. Esco Vaccixcell offers complete documentation of system parts.