Animal viruses are of great concern to humans for two main reasons: economic losses and human threats.

When an animal epidemic breaks out, the economy suffers grave losses due to agricultural losses, as the infected animals can die or their meat, milk, and other products are no longer fit for human consumption. Moreover, sanitation and immunization in farms are not well established and thus, diseases can easily spread among the herd, leading to further losses.

Zoonotic infections are animal diseases that can infect human beings, thereby putting humans in grave danger; examples of these zoonotic infections include rabies, hand, foot, and mouth disease (HFMD), and MERS-Cov. Transmission of zoonotic infections usually take place through bites, contact with fluid from infected animal or consumption of raw/undercooked/unpasteurized meat/milk/etc. from the infected animal. Studies have shown that about 60% of infectious diseases in humans are from animals. Human vaccines against these animal diseases are continuously being developed but are expensive and unavailable in remote areas.

The most ideal solution for these animal diseases is eradication at source, which means immunization of the animals themselves; however this would require the production of large quantities of vaccines at minimal costs. VacciXcell’s solution to this is the tide motion bioreactor system.

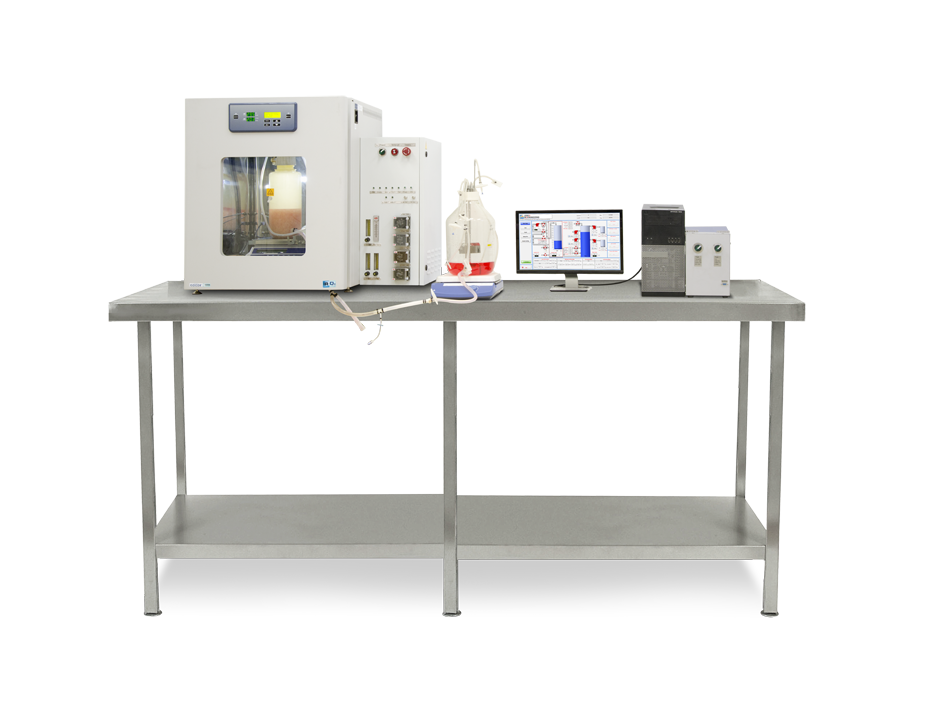

First, VacciXcell’s tide motion system offers the highest productivity, as compared to other adherent bioreactors used in animal vaccine production. A single TideCell® 100L unit can replace up to 20,000 roller bottles, with a much smaller footprint, lower risk of contamination, and lower labor requirement.

| Model | Fixed Bed Volume (L) | Culture Surface Area (m2) | Equivalent RB-850 (850 cm2) | Equivalent DS-40 (25,200cm2) | Equivalent Cytodex II (0.44 m2/g) |

| CelCradle™ | 0.1 | 1.65 | 20 | 0.65 | 3.75g |

| TideCell® 2L | 1 – 4 | 66 | 900 | 26 | 150g |

| TideCell® 10L | 5 – 10 | 165 | 2,000 | 65 | 375g |

| TideCell® 20L | 10 – 20 | 330 | 5,000 | 130 | 750g |

| TideCell® 100L | 50 – 100 | 1,650 | 20,000 | 650 | 3,750g |

Second, VacciXcell’s Tide Motion bioreactor is the only system that has truly broken the adherent scale-up barriers; scale up can be done with minimal parameter optimization, thereby reducing bioprocessing costs and time. Scale-up with macrocarrier in stirred tank bioreactors cannot be simply done by using a larger system; intensive optimization of interrelated parameters must be performed to ensure high productivity without compromising the quality of products. Other packed bed bioreactors have limited scalability, as they suffer from oxygen limitation; oxygen transfer in these systems happen from the air to culture medium (in the form of bubbles) then to the cells. This 3-step oxygen transfer can be slow and may limit cell growth. VacciXcell’s tide motion system overcomes this through its dual oxygenation scheme, wherein cells can obtain oxygen through the aeration phase and the nutrition phase (via the dissolved oxygen in the culture medium). On the other hand, scale up with roller bottles is simply done by multiplying the number of bottles; however, this incurs large labour and space requirements and also has a high risk of contamination.

For these reasons, VacciXcell’s TideCell® System can be easily scaled up from laboratory scale to 5000L!

Third, animal vaccines must be produced in large quantities at very low costs. Apart from the cost reduction during bioprocess scale-up, VacciXcell’s tide motion system also help reduce downstream processing costs. Cells remain entrap within the BioNOC™ II macrocarriers; thus secreted viruses or virus particles can easily be harvested with the culture medium. This reduces recovery costs, as compared to microcarrier systems, wherein the separation of microcarriers from the culture medium incurs additional downstream processing costs.

Fourth, Production wild-type viruses or BSL3/4 viruses require high running costs in terms of facility containment requirements and HVAC systems, in order to prevent the risk of operator exposure or accidental leak to the environment. VacciXcell’s TideCell® System overcomes this problem, as it is the only bioreactor system that can be placed inside a cGMP isolator, which can contain up to BSL-4 viruses. This greatly reduces the production costs of vaccines against BSL3/4 viruses, such as HFMD, and wild-type viruses, ideally for seasonal influenza, as this eliminates the need to build and run cleanrooms. Moreover, VacciXcell’s TideCell® Incubation System increases operator and environment protection by incorporating ULPA-filtered exhaust air and optional hydrogen peroxide biodecontamination system.

Finally, the TideCell® System has been successful in the production of different animal vaccines using various cell lines. It has been used for the production of hog cholera virus using PK and ST cell lines, and also WEE virus using the CEF cell line and as well as for the research of hand, foot, and mouth disease, and other virus. The following tables show productivity comparison data for different veterinary vaccines.

Table 1. Performance and Cost Analysis for Bovine Vaccine

| Feature | Other Packed Bed Bioreactor | TideCell® 20L |

| Performance Analysis | ||

| Scale | 5 L | 20 L |

| Carrier | 200 g | 1100 g |

| Max. cell density per unit | Unknown (not able to count cells) |

2×1011 |

| Culture days | 5 | 5 |

| Average Virus concentration | Log 8.5 TCID50/ml | Log 9.0 TCID5/ml |

| Culture medium (cell culture) | 20 L | 500 L |

| Virus production days | 4 | 4 |

| Culture medium (virus production) |

25 L | 500 L |

| Equivalency | 63 | 1 |

| Cost Analysis | ||

| Space | 95 m2 | 3~6 m2 |

| Labor | 30 | 2 |

| Culture medium | 2,835 L (~USD28,350) | 1,000 L (~USD 10,000) |

Table 2. Performance and Cost Analysis for Hog Cholera Vaccine

| Feature | Roller Bottle | TideCell® 10L |

| Performance Analysis | ||

| Scale | 15 L, 3000 cm2 per bottle | 10 L |

| Carrier | None | 550 g |

| Max. cell density | 4~6×108 | 1×1011 |

| Average Virus concentration | 40 mil. RID/ml | 200 mil. RID/ml |

| Culture days | 3 | 3 |

| Culture medium (cell culture) | 1.5 L | 50 L |

| Virus production days | 16 | 28 |

| Culture medium (virus production) |

6 L | 720 L |

| Equivalency | 443 | 1 |

| Cost Analysis | ||

| Space | 100 m2 | 3~6 m2 |

| Labor | 10~20 | 2 |

| Carriers | 550 g | |

| Culture medium | 2,658 L (~USD26,580) | 720 L (~USD 7,200) |

Table 3. Performance and Cost Analysis for Rabies Vaccine

| Feature | Roller Bottle | TideCell® 10L |

| Performance Analysis | ||

| Scale | 15 L, 3,000 cm2 | 10 L |

| Carrier | None | 550 g |

| Max. cell density | 4~6×108 | 1×1011 |

| Culture days | 3 | 4 |

| Culture medium (cell culture) | 1.5 L | 290 L |

| Virus production days | 4 | 6 |

| Virus titer | 107~8 TCID50/ml | 108.5~9 TCID50/ml |

| Culture medium (virus production) | 1.5 L | 65 L |

| Equivalency | 226 | 1 |

| Cost Analysis | ||

| Space | 100 m2 | 3~6 m2 |

| Labor | 10~20 | 3 |

| Carriers | None | 550 g |

| Culture medium | 678 L | 355 L |

Sign up to our newsletter and receive the latest news and updates about our products!