Cellular agriculture is now on the rise due to the impact of livestock and poultry industries on the environment, animal ethics, and even human health. The rising global population equates to higher demand for protein products - requiring technologies that are more sustainable, ethically sound, and environment-friendly.

Cellular agriculture involves the production of animal products through culturing methods. These products include whole cell (cellular product) and also animal biomolecules, such as proteins and fats (acellular product). Cellular products encompass tissue engineering, and cultivated or cultured meat.

In this case, cultured meat refers to the application of cultured methods to produce muscles that are rich in protein for human consumption. There are numerous existing terminologies referring to such cultured meat including in vitro, cultivated, and clean meat. The differences arise from consumer preferences, political sensitivities, and opinions of different groups.

The lack of framework and regulations regarding this subject matter is very apparent yet intensive researches are already underway.

Tissue engineering methods have been used to culture muscle cells mimicking in vivo environment. A scaffold is required to allow adhesion, proliferation and maturation of the muscle cells. Edible scaffold such as collagen microspheres are ideal as these would not need to be extracted from the cultured meat product. For non-edible scaffolds, however, cultured muscle cells are separated first prior to harvesting; since this procedure might damage the muscle cells, protective techniques such as thermoresponsive coatings are used. This will enable the easy release of cultured cells upon cooling, thus, eliminating the risk of damage to the cells.

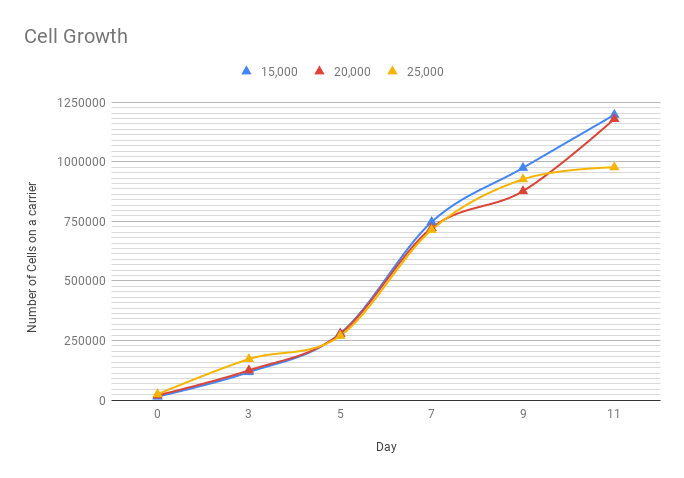

The Tide Motion system has been applied in culturing adherent C2C12 cells, model for skeletal muscle cells. The cells grow on non-edible macrocarriers that mimics a 3D in vivo environment. Confluence is achieved at day 6-8 with ~33 fold increase achieved from the lowest seeding density of 15,000 cells/carrier. This demonstrates the applicability of the Tide Motion system for the efficient growth of adherent muscle cells from low seeding densities.

Figure 1. Growth curve of adherent C2C12 cells in the Tide Motion bioreactor.

Our Tide Motion bioreactors provide a single-use capability to ensure that the resulting cultured adherent muscle cells are manufactured under robust condition. The controlled environment would ensure repeatability and quality in the production process, providing an easy way to transition to any system that regulations may place in the future.

References:

Natalie Rubio, Isha Datar, David Stachura, David Kaplan, & Kate Krueger. (2019). Cell-Based Fish: A Novel Approach to Seafood Production and an Opportunity for Cellular Agriculture. Frontiers in Sustainable Food Systems. https://doi.org/10.3389/fsufs.2019.00043

Neil Stephens, Lucy Di Silvio, Illtud Dunsford, Marianne Ellis, Abigail Glencross, & Alexandra Sexton. (2018). Bringing cultured meat to market: Technical, socio-political, and regulatory challenges in cellular agriculture. https://doi.org/10.1016/j.tifs.2018.04.010

Sign up to our newsletter and receive the latest news and updates about our products!